Magnetic Particle Inspection

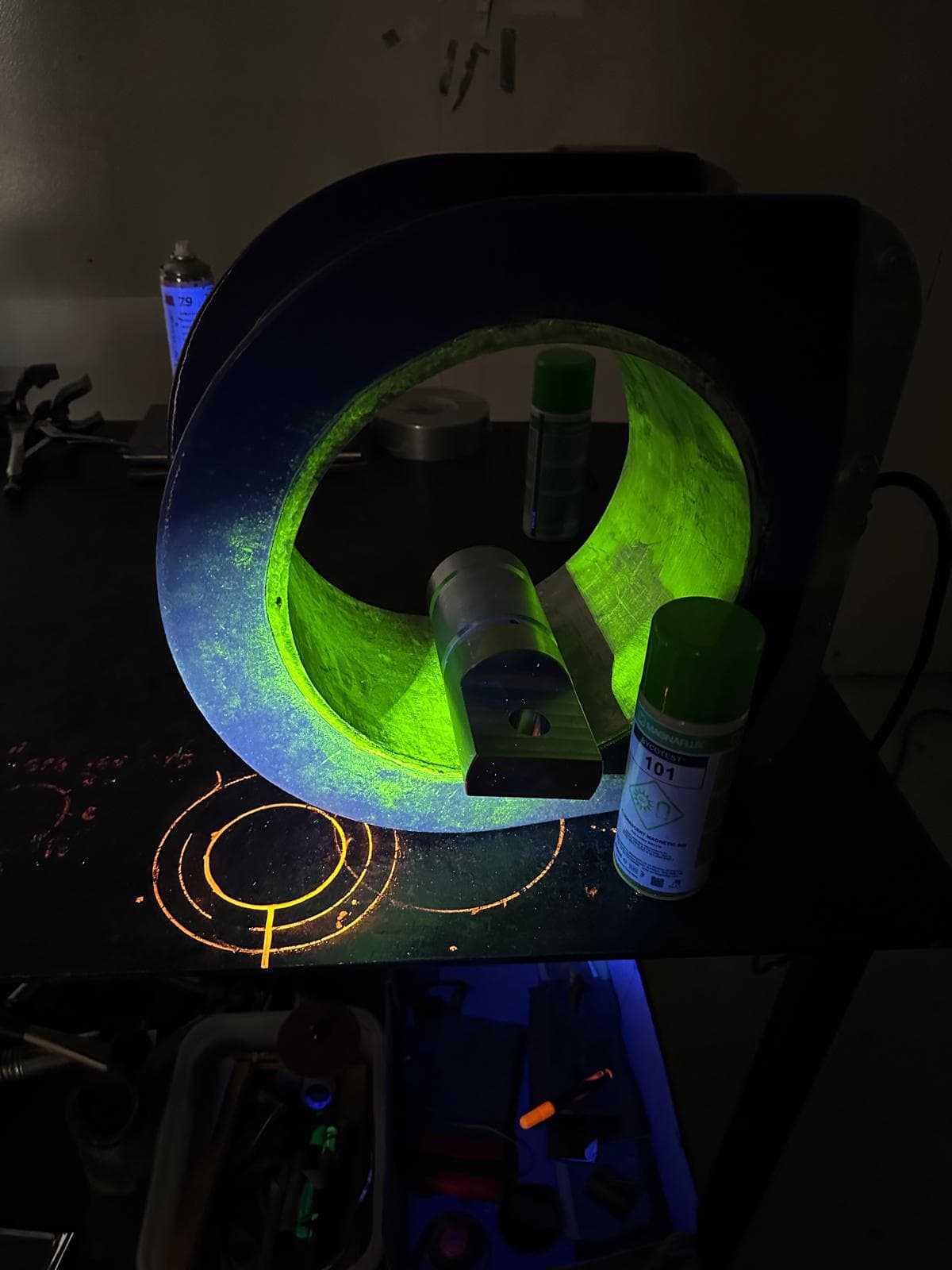

Magnetic particle inspection (MPI) is a powerful non-destructive testing (NDT) method used to detect surface and near-surface flaws in ferromagnetic materials. This technique relies on the principles of magnetism to identify defects such as cracks, laps, seams, and other discontinuities that may compromise the integrity of the material.

How it works:

During magnetic particle inspection, the test object is magnetized either by direct magnetization (using a magnetic field created by a yoke or prod) or by indirect magnetization (using an electromagnet or permanent magnet). A fine magnetic particle suspension, typically iron particles suspended in a liquid or dry powder form, is then applied to the surface of the magnetized object.

If there are any surface or near-surface defects present, they will disrupt the magnetic field, causing the magnetic particles to be attracted to and accumulate around the defect, forming a visible indication or "magnetic particle indication" that can be easily detected and interpreted by trained inspectors.

Applications:

MPI is widely used across industries such as aerospace, automotive, manufacturing, marine, and construction for the inspection of welds, forgings, castings, pipelines, and other critical components. It is particularly effective for detecting defects that are open to the surface, making it an essential tool for quality assurance, maintenance, and safety assessments.

Rapid inspection of large surfaces

Detection of surface and near-surface defects

Immediate interpretation of indications

Relatively low equipment cost

Versatile: Ideal for both workshop and on-site use

Simplified surface prep: Less critical than Penetrant Testing (PT)

Flexible methods: 'Colour-contrast' for standard, 'fluorescent ink' for high sensitivity in dark environments

Other Services

Check out our other services

Radiography

Our radiography services are designed to provide you with the insights needed to make informed decisions.

Ultrasonic Inspection

Our ultrasonic inspection services are designed to ensure the safety and reliability of your assets.

Visual Inspection

Our visual inspection services are designed to provide you with the insights needed to make informed decisions.

Liquid Penetrant Inspection

Our liquid penetrant inspection services are designed to provide you with the insights needed to make informed decisions.

Hardness Testing

Our hardness testing services are designed to ensure the safety and reliability of your assets.

Positive Material Identification

Our positive material identification services are designed to provide you with the insights needed to make informed decisions.